Most wood will deteriorate very rapidly during outdoor exposure without some protective coating.

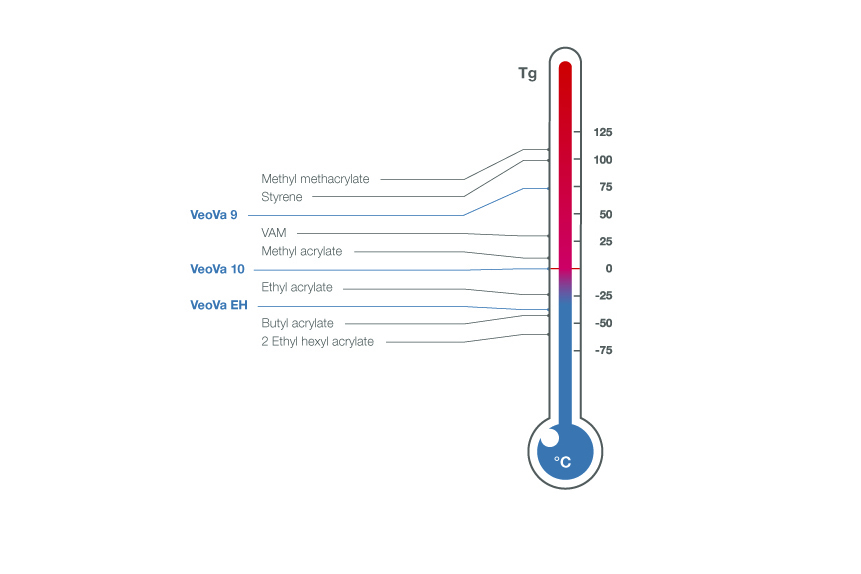

Acrylic polymers modified with VeoVa™ monomers (VeoCryls), are particularly suitable for high-performance exterior wood coatings. The core / shell technology can be used to obtain polymers with a very good balance between hardness and flexibility.

VeoCryl-based coatings provide longer lasting wood protection through increased water repellence, UV resistance and increased adhesion to wood, resulting in improved weathearability and longer exterior durability.

Deliver coatings as flexible and versatile as the wood itself, VeoVa Silane technology coatings can provide resistance against weathering, scratches and wear, while remaining sufficiently flexible. With the short drying and early tack-free times of a 1K system, processing is quick and easy.

Cardura E10P glycidyl ester can be converted into a hydroxyl-functional acrylic monomer by reaction with (meth)acrylic acid. The Cardura E10P glycidyl ester-based hydroxyl acrylate building block allows polymer designers to tailor the hydroxyl-functional emulsions for a specific desired end-use from wood and protective coatings to wall, floor and high performance top coats.

.df3032dc.jpg)

.2f154618.jpg)

.3b3c8e84.jpg)